Data-driven repair planning leverages historical data, parts trends, and customer preferences to streamline car bodywork services in today's digital age. Advanced analytics identify patterns for efficient solutions, enhancing quality and reducing costs. Predictive maintenance uses historical records and sensor data to anticipate equipment failures, optimizing maintenance scheduling and cutting costs. Efficient resource optimization through data insights ensures workshops handle varying workloads promptly, boosting customer satisfaction by delivering timely services.

In today’s digital era, understanding the intricacies of data-driven repair planning is a game changer. Unlocking efficiency through data analysis revolutionizes traditional maintenance strategies. This article delves into three critical aspects: unsealing efficiency with data’s role, implementing predictive maintenance for accurate forecasting, and optimizing resource allocation in repair logistics. By leveraging data effectively, organizations can significantly enhance operational productivity and minimize downtime.

- Unlocking Efficiency: Data's Role in Repair Planning

- Strategies for Accurate Predictive Maintenance

- Optimizing Resources: Efficient Repair Logistics

Unlocking Efficiency: Data's Role in Repair Planning

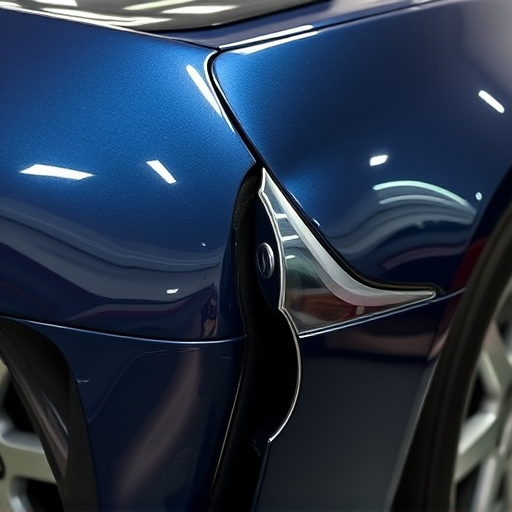

In today’s digital era, embracing data-driven approaches has become a game-changer for numerous industries, and car bodywork services are no exception. By leveraging data, repair planning processes can be transformed into efficient, precise operations. This shift towards data-driven repair planning enables workshops to streamline their workflows, reduce time wastage, and optimize resource allocation. With access to historical data on past repairs, parts usage, and customer preferences, car paint services can anticipate future demands and tailor their inventory accordingly.

Furthermore, advanced analytics can identify patterns and trends in car paint repair cases, allowing professionals to develop more effective solutions. This not only enhances the quality of repairs but also contributes to cost savings. Data-driven insights enable experts to make informed decisions, ensuring that every step in the repair process, from assessing damage to selecting the right materials, is optimized for efficiency and accuracy, ultimately delivering superior car bodywork services.

Strategies for Accurate Predictive Maintenance

In the realm of data-driven repair planning, accurate predictive maintenance is paramount. By leveraging advanced analytics and machine learning algorithms, automotive repair services can anticipate equipment failures before they occur. This proactive approach involves analyzing historical maintenance records, sensor data from vehicles, and operational patterns to identify trends and predict when repairs or replacements are likely needed. Such insights enable mechanics and fleet managers to schedule maintenance activities optimally, minimizing downtime and reducing the cost of unexpected breakdowns.

For instance, in the context of vehicle paint repair and car restoration, predictive models can forecast when coating failures are probable based on factors like environmental conditions, driving patterns, and age of the vehicle. This allows for targeted interventions, such as scheduled touch-ups or complete overhauls, ensuring that cars remain in top condition throughout their service life. Integrating these strategies into data-driven repair planning not only enhances operational efficiency but also contributes to the longevity and performance of vehicles, catering to customers’ needs for reliable and aesthetically pleasing automotive repair services.

Optimizing Resources: Efficient Repair Logistics

In the realm of data-driven repair planning, efficient resource optimization is key to enhancing overall workshop productivity. By leveraging insights from historical data, collision repair centers can streamline their logistics and allocate personnel, parts, and equipment more effectively. This means minimizing downtime and maximizing utilization rates for every service offered, including dent repairs, bumper repairs, and other common services.

For instance, predictive analytics can anticipate peak demand periods, allowing proactive staffing and inventory management. Real-time tracking of repair workflows enables managers to identify bottlenecks and adjust resource allocation accordingly. Such strategic planning ensures that the workshop is well-equipped to handle varying workloads, resulting in faster turnaround times for customers. Efficient repair logistics not only reduces operational costs but also enhances customer satisfaction by providing timely service, making it a crucial component of any successful data-driven repair planning strategy.

Data-driven repair planning is transforming the way maintenance is approached, offering significant improvements in efficiency and cost savings. By leveraging predictive analytics and optimizing logistics, organizations can enhance their repair processes, ensuring a more accurate, timely, and resource-efficient approach. Embracing data-driven strategies enables businesses to stay ahead of potential issues, reduce downtime, and ultimately improve overall equipment effectiveness. This shift towards data-driven decision-making is a key step in achieving success in today’s competitive market.